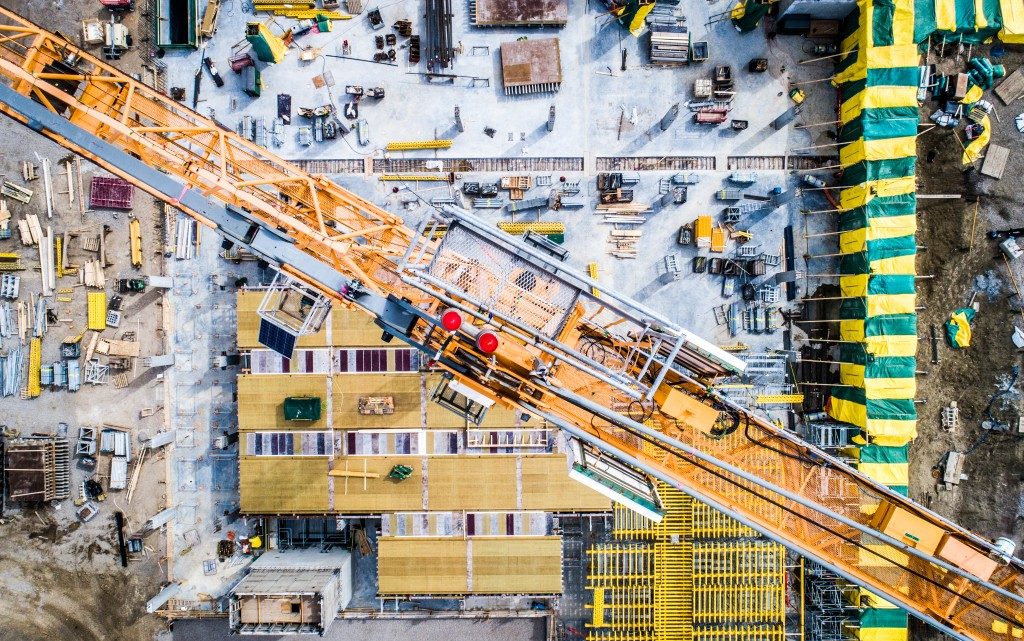

When you are working on a construction site that involves extensive excavation work, such as that usually required for building foundations, the groundwater table level becomes an important consideration. A dry foundation is essential to structural stability and worker safety at the site. However, most soils are relatively permeable, and groundwater will enter the area as you dig.

Dewatering your site thus becomes necessary to continue your operations. Here are three key points when determining how you’ll go about this crucial operation.

Method of dewatering

The most common method of dewatering for construction sites is known as open sump pumping. In this method, groundwater is allowed to seep into the excavation area. From here, a handling pump can quickly discharge the collected water. Sump pumping is very economical, as you allow gravity to do much of the work. However, it works best in gravelly or sandy soil, and the excavation site may be at risk of instability due to the action of water throughout the process.

A variety of pre-drainage methods may be used to ensure stability at your construction site while removing excess groundwater. Wellpoint drilling is a widespread technique in which a series of wells are drilled around the site before excavation. Pipes are installed into the wells, and a piston pump is used to draw out the water. This method is effective to a depth of about 5-6 meters below the level of the wellpoint pump and is thus suitable for many construction specifications.

Other methods may also be employed to accommodate unusual soil types or foundation requirements. Consult with a groundwater specialist if necessary to determine the best method applicable to your site.

Treatment of the water

Collected water must be inspected and treated as part of your operation’s responsible practices. Untreated water removed from your construction site will contain various sediments which adversely affect the quality of the nearby bodies of water where they will eventually be discharged.

Sediments must be filtered from the water by flowing to a designated treatment structure, such as a stormwater basin, with a physical barrier to prevent sediment discharge. The water flows through a sediment trap, which can be a filter bag or silt fence that traps a majority of particles, and this can be further enhanced with a chemical treatment to bind more pollutants. If the water is contaminated with oil, grease, or other petroleum products, use an oil separator to remove it.

Discharge location

You should carefully select the location where your treated water will be discharged. Depending on your location, local authorities may not permit direct discharge into protected bodies of water. Even if your site is far from a lake, stream, or wetland, you should consider the possible impact of this volume of discharged water on erosion in the area.

For these purposes, it’s recommended that you divert the discharged water to an area with a buffer of vegetation. Grasses or wooded growth can provide suitable erosion resistance. You should continue to monitor this area for signs of instability or erosion and immediately cease and relocate the discharge if that happens.

Effective dewatering is standard practice at construction sites where excavation is required. Make sure it’s done effectively and responsibly to ensure the stability of your structure and minimise the effect on the environment.